How to save electricity (=money) with a compressed air system?

Use variable speed drive (VSD) compressors. Compressors with frequency converters adjust the motor speed according to the actual compressed air demand.

Advantages:

– 30-50% reduction in energy consumption

– Fewer load/idle cycles

– More stable pressure and less wear

Suitable for systems where compressed air consumption varies. The best results are achieved when combining a VSD and a fixed speed compressor.

Choose a compressor of the appropriate size.

– Oversized compressors operate inefficiently. Use consumption data to select the correct size.

Use smart control systems and air tanks.

– Properly sized compressed air tanks help smooth out peak loads

– Sequencing control optimizes the operation of multiple compressors more efficiently

Reduce system pressure.

– Every 1 bar pressure reduction results in approximately 7% energy savings.

– Keep system pressure as low as possible while maintaining reliability.

Repair air leaks in the plumbing.

20-30% of the compressed air produced can be lost due to leaks. Use ultrasonic leak detectors:

– Hoses

– Fittings

– To check valves

For example, a 3 mm hole at 7 bar pressure can cause significant costs per year. Create a leak management program.

Avoid unnecessary use of compressed air – compressed air is an expensive energy source.

Don’t use this:

– For cleaning dust

– For cooling

– For ventilation

Use a blower or fan instead.

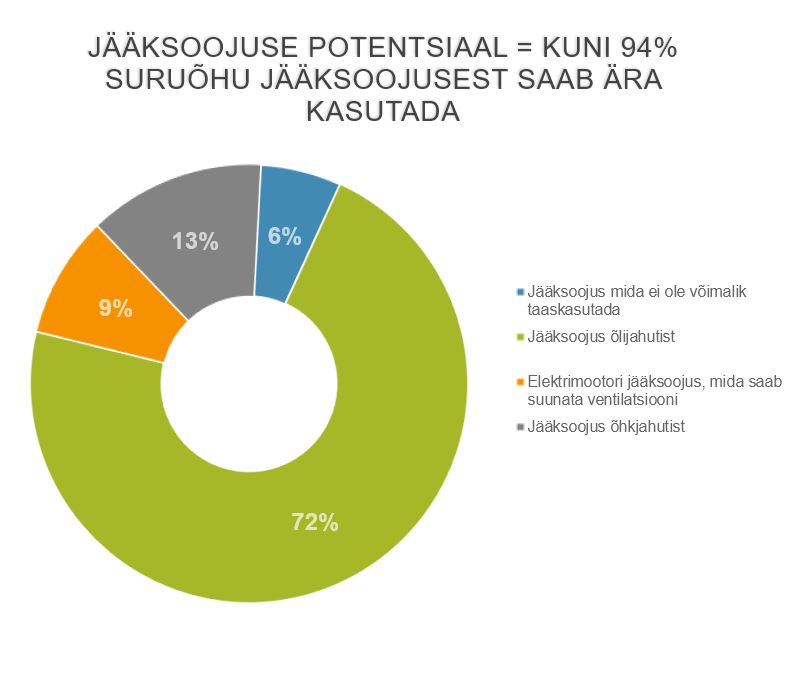

Reuse the compressor’s heat – install a heat exchanger or add heat recovery to the compressor’s ventilation system.

Up to 90% of the compressor’s input energy is converted into heat. It can be used:

– For preheating industrial water

– For heating production facilities

– For process heat

Savings: up to 70-90%. Payback period less than 2 years.

Summary

The most important energy saving measures.

Compressors with frequency converter – potential savings of 30-50%

Heat recovery – potential savings of 70-90%

Leak elimination – potential savings of 20-30%

Pressure reduction – potential savings of 7% for every bar