We offer a wide range of gas compressors for various industrial and technical fields. Below you will find an overview of the main devices and product lines we represent – this is not a complete list.

Every application is different and often the solution requires a configuration that meets specific pressure, gas and operating conditions. Therefore, we recommend that you contact us even if you cannot find a suitable solution in the list – in cooperation with the manufacturer, we can usually offer a gas compressor that meets your needs.

Our main selection includes two recognized manufacturers: JP Sauer & Sohn from Germany and their group HAUG Sauer Kompressoren from Switzerland. If necessary, we can also help with the selection, maintenance or technical advice of gas compressors from other manufacturers.

JPSauer & Sohn offers a wide range of gas compressors based on their proven piston compressor technology.

Gases used:

-

– Nitrogen (N₂)

-

– Helium (He)

-

– Argon, neon, other inert gases

-

– Natural gas and technical mixed gases

Features:

- – Gas-adapted materials and seals

- – High level of safety and leak-proof design

-

– ATEX and special solutions possible

-

– Up to 1000 m3/h and 500 bar (not for every gas, more detailed technical possibilities will be clarified upon receipt of initial data)

-

Suitable for:

-

– Energy and chemical industry

-

– Gas recovery and booster systems

-

– Research and testing laboratories

-

Sauer Haug compressors overview - oil-free, hermetically gas-tight solutions

Sauer HAUG is a world-renowned brand of oil-free and gas-tight piston compressors used in demanding industrial and process environments where process cleanliness, safety and reliability are important.

HAUG compressors are ideal for compressing and recovering gases , especially when:

-

pollution-free and oil-free work is required,

-

the process environment is sensitive (e.g. medicine, chemistry, food production),

-

The absolute gas density of the gas is important.

All HAUG compressors are based on modular design technology that can be adapted to the customer’s application.

HAUG compressors are suitable for processing and pressurizing many gases , such as:

-

Nitrogen (N₂), oxygen (O₂), air, helium (He) — pure compressors

-

SF₆, CO₂, argon (Ar) — special technical gases

-

CNG, biomethane, other gases related to energy production

-

Special clean processes (e.g. medicine, electrical industry)

HAUG’s main product series:

-

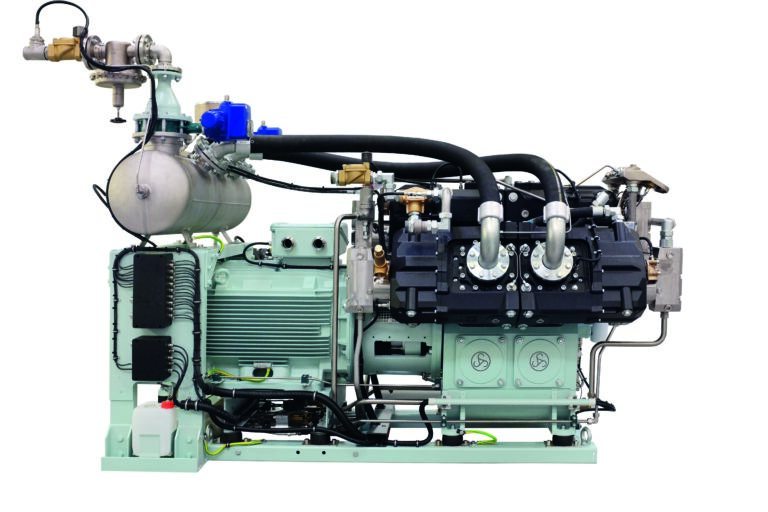

HAUG.Pluto – compact oil-free gas compressor

-

– Lower power and compact dimensions.

-

– Suitable for pressurizing smaller amounts of gas (e.g. air, nitrogen, helium, oxygen, SF6).

-

– Gas-tight and oil-free design ensures clean operation without contaminants.

-

Suitable for: laboratory systems, small production lines, R&D equipment.

-

– Used for gas recovery and booster pressurization such as: helium, SF6, oxygen, nitrogen, biomethane and CNG .

-

– Oil-free, dry-running and hermetic design with integrated motor.

-

– Compact, quiet and suitable for workplaces where space is limited.

-

Suitable for: energy and gas industry, laboratories, medical systems.

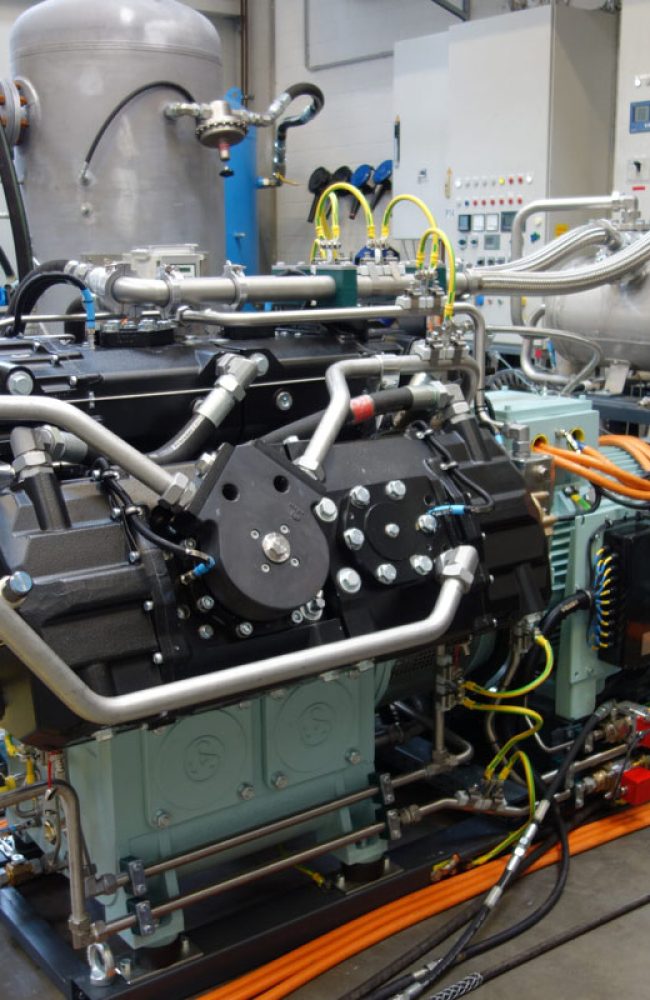

- HAUG.Sirius – an efficient and flexible industrial solution

-

– Historically one of HAUG’s most classic and most popular series (since the 1970s).

-

– Magnetic coupling ensures permanent hermetic gas-tight operation .

-

– Pressure up to ~100 barg, flow rate up to ~1000 Nm³/h.

-

– Available in both air-cooled and water-cooled variants.

-

Suitable for: large process and energy industry applications.

-

– Pressurizes almost all gases thanks to the magnet. connection and robust construction.

-

– Can be customized to specifications, including EX solutions.

-

– Higher flow and pressure versions up to ~100 m³/h and ~100 barg.

-

Suitable for: process and chemical industries, gas processing systems.

Hydrogen (H2)

More and more news is appearing about hydrogen as a new output of green energy. Every week new possibilities are found where hydrogen could be used and how it can be produced, compressed or transported more cheaply. Hydrogen is a very common element in the world, but it is also flammable and explosive. Therefore, it is necessary to choose very carefully which equipment to use in your hydrogen compressor station, pipeline or transport to ensure that they are safe and energy efficient.

Kompressorikeskus offers a wide range of gas compressors for increasing the pressure of hydrogen, which are suitable for use in very different areas, such as transport (hydrogen filling stations for cars, buses, etc.), industry, energy, etc. Since the pressure and quantities of hydrogen are very different in different areas, we can offer a pressure increase to 20 bar, but also to 1100 bar if necessary. When making a request, please always include as much basic data as possible – these are definitely the field you are working in, the gas input pressure to the hydrogen compressor and the desired output pressure, as well as the input and ambient temperature.

Hydrogen storage, piping, fittings, etc.

Our selection includes tanks made of different materials, which are suitable for hydrogen – metal hydrogen tanks and hydrogen tanks made of composite material. The offered hydrogen tanks are manufactured in Poland and England. For more detailed information, please send a request, be sure to mention the field, maximum pressure and tank volume.

Any type of pipes, hoses or fittings must not be used with hydrogen. Due to the characteristics of the gas, today there are only selected manufacturers in the world who have the certificates to produce the correct hydrogen pipe or fitting. Together with our partners, we can put together a solution that is exactly right for you. We are able to offer both solutions for building a trunk pipe indoors or connecting equipment, as well as trunk pipes in the form of outdoor routes.